Flow Reactors

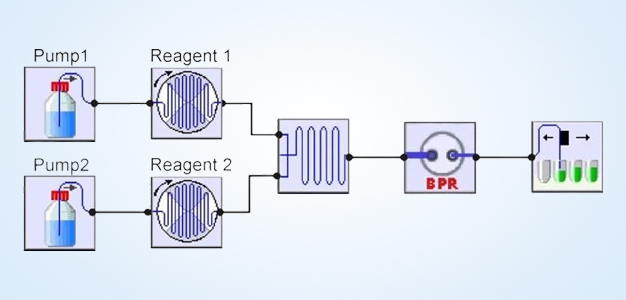

Flow chemistry considered as future of all industries, also described as microchemistry, plug - flow or continuous chemistry offers an efficient, more productive and safer alternative to traditional batch techniques for the manufacture of pharmaceuticals, agrochemicals and other fine chemicals at large scale.

We at Qualitas Techno Solutions which is led by team of chemical and instrumentation engineers having vast experience in development and execution of process in Flow Reactor from lab to commercial, help client to understand the basics of flow chemistry and study the safe application of Flow Reactor.

We strive to provide solution to Client with their existing project as well as new project which can be performed in Flow Reactor as well as other Upstream and Downstream process.

Flow Reactors is a new solution in performing chemical reaction by delivering raw materials into micro channels. Flow reactor enables various types of reactions which could not have been performed in a conventional batch mode (flask, vessel).

Flow Reactor differs from conventional Batch Reactor by having the following important features :

- Safety : Ability to withstand extreme conditions because of smaller reaction volumes. Safe operation.

- Control of reaction time : Smaller residence time, which helps carry out fast reaction at true kinetics.

- Control of stoichiometry : Concentration of either reactants can be changed by increasing or decreasing the flowrate as per the stoichiometry.

- Heat transfer : Excellent heat transfer due to the much greater surface area to volume ratio which helps to carry out exothermic reaction.

- Mass transfer : Sufficient interfacial area and surface renewal rate is available for the rapid mass transfer.

- Scalability : Rapid, predictable scale -up from kg to ton without re-optimization orchange in mixing efficiency.

Our Expertise :

- Basic and detailed engineering for new and existing process.

- Product development from lab to commercial.

- Quick feasibility test.

- Customized turnkey solutions.

- Technical support.

- Instrumentation and Automation.

- Complete Digitalization as per Industry 4.0

Model: Cor_Flow 25

Features

- Vol: 25 ml

- MOC:SS316

- Five sampling port and five temperature monitoring points

- Ideal for lab scale study.

- Helps to carryout kinetic study in less time and material.

- Fully automated system.

- Can be placed in walking hood.

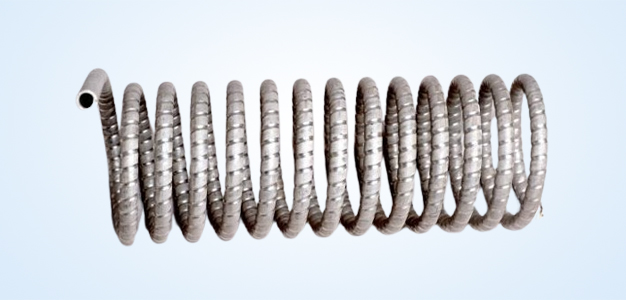

Model: Cor_Flow 100

Features

- Vol: 100 ml

- MOC:SS316

- Designed for better mixing and heat transfer.

- One sampling port and mixing point temperature monitoring

- Ideal for lab scale as well as for industrial case study.

- Helps to carryout kinetic study in less time and material.

- Fully automated system.

- Can be placed in walking hood.

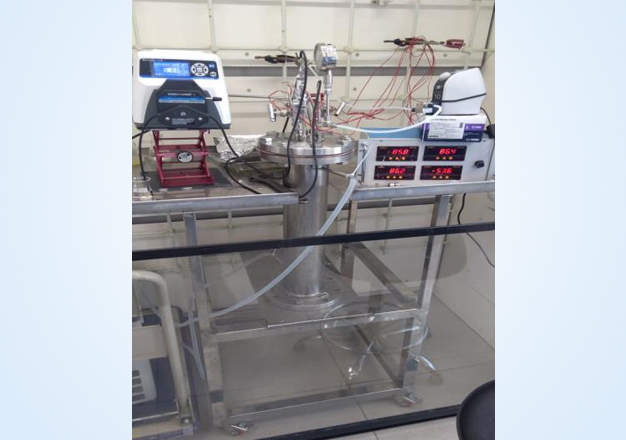

Model: Cor_Flow P500

Features

- Vol: 500 ml

- MOC:SS316

- Designed for better mixing and heat transfer.

- One sampling port and mixing point temperature monitoring Quenching can be done inside.

- Ideal for industrial case study and can be used as a pilot plant.

- Helps to carryout kinetic study and can be easily scaled up to any size.

- Fully automated system.