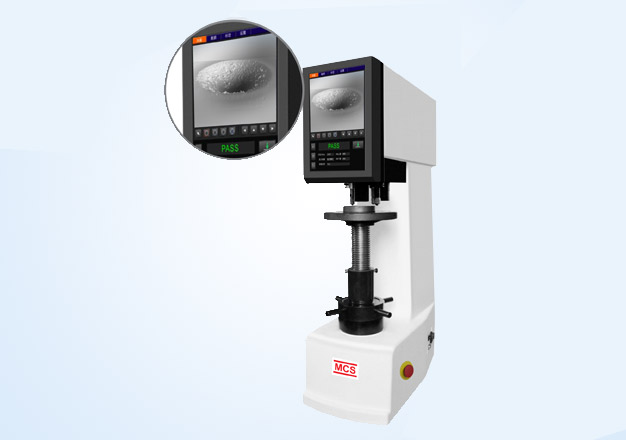

Rockwell Hardness Tester With Touchscreen

Model : RHT-TS

Features :

- Fully automatic, motorised opertation

- Fully Touch Screen Rockwell Hardness Testing Machine.

- Accurate Measurement of Rockwell Hardness number using “State of the art” image processing technology.

- High accuracy & repeatability of measurement at all loads.

- Faster measurement yielding to higher productivity.

- Motorised loading and unloading cycle.

- Facility to export result / data in PDF format.

- USB Printer/Wi- fiprinter port for printer interface with result & graph print-out.

- Batch file processing with statistical analysis.

Construction : The robust machine frame is designed to accommodate the high precision loading equipped with industrial touch screen. The accurate load is applied on a diamond indenter by means of lever and weights. After a specific lapse of time the load is released automatically. The image is digitalized using USB camera fitted in the machine & is captured by the front touch screen. The diagonals of the indentation are automatically measured by software to give the Rockwell hardness number.

- Steel Ball Indentor 1/8", 1/4", 1/2".

- Test Blocks (for A,B,C,D,E,F,G,H,K,L,M,P,R,V)

- Testing Table 200 mm dia.

- Testing Table 70 mm dia. With 'V' groove for round jobs

- Jominy text fixture for end quench test.

- Special Diamond Indentor suitable for Gooseneck Adaptor No.1

- Special Diamond Cylinder anvil for jobs above 20 mm dia.

- Everyball anvil with 25.4 dia. Or 38mm dia. Ball

- Gooseneck anvil for pipes 5 to 25 mm ID with 5 mm step inserts

Technical Specifications :

| Load Application | Motorized loading & unloading |

| Hardness Scales | Rockwell (HR), Rockwell Superficial (HR-N) |

| Rockwell Test Loads | 15, 30, 45, 60, 100, 150 kg |

| Rockwell scale | A,B,C,D,E,F,G,H,K,L,M,P,R,S,V |

| Rockwell Superficial Scale | 15T,30T,45T,15N,30N,45N, 15W,30W,45W,15X,30X, 45X,15Y,30Y,45Y |

| Rockwell Resolution(Depth) | 0.1 |

| Rockwell Standard | IS:3804, BS 10109-2 & ASTM E-18 |

| Superficial Standard | IS:5073, BS 10189-2 & ASTM E-18 |

| Max. Test Height | 230 mm |

| Depth of Throat | 133 mm |

| Dwell Time | 1 to 99 seconds |

| Data Output/Connectivity | USB / Wi-Fi (Optional) |

| Operating temp Range | 10 to 35 degree celsius |

| Power Supply | 230 V AC, 50 Hz, Single Phase |

Standard Accessories :

| Diamond Indentor | 1 No. |

| 1/16" Ball Indentor | 1 No. |

| HRC/HRB/HRN- Test Blocks | 1 No. each |

| Testing Table - Flat - 50mm dia. | 1 No. |

| Teting Table - V Groove 38 mm dia | 1 No. |

| Allen keys (1.5 / 2 / 2.5 / 3 / 4 / 5 / 6) | 1 No. each |

| Screw drivers | 1 No. |

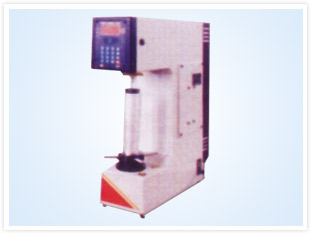

Digital Hardness Testers

Digital Hardness Tester for Rockwell Tests has motorized automatic cycle operation i.e. load/dwell/unload. The Preliminary Test Force is 98.07N (10kgf). Total Test Force is 588.4, 980.7, 1471N (60,100,150 kgf). Test Force Selection is by external mechanical dial. The system has bar indication on display for Preload. User can set Preload Dwell time, Dwell time for Total Load and Elastic recovery Dwell time. The operation is easy with keyboard entry through reliable membrane switches for scale/HI-GO-LO/Dwell time selection. The scale display is with 0.1 Rockwell Resolution.

The system has real time measurement with Digital Dial Indicator of 1 micron resolution.

The machine has feature of data export to PC or serial printer. It gives results indicating serial number of tests, hardness scale, hardness value and high / good / low indication w.r.t limits entered.

The Digital Rockwell Hardness Tester (MCS-RASNE) covers Rockwell scale A, B, C, D, E, F, G, H, K, L, M, P, R, S, V and confirms IS : 3804, BS 10109-2 & ASTM E-18. The Digital Rockwell Superficial Hardness Tester (MCS-RASNE/S) includes all Rockwell scales and 15T, 30T, 45T, 15N, 30N, 45N, 15W, 30W, 45W, 15X, 30X, 45X, 15Y, 30Y, 45Y and confirms IS : 5073, BS 10189-2 & ASTM E-18

Also Available is

MCS-RASE - Basic Rockwell Machine with digital readout interface with all above features except manual load/unload cycle. MCS-RASE/S - MCS-RASE with Superficial Hardness Tester scales

Optional Accessories

• External serial thermal printer to print reports

• PC software to interface machine to computer

Principle :

Rockwell & Rockwell superficial tests consist of forcing an indentor (Diamond or Ball) into the surface of a test piece in two steps i.e. first with preliminary test force and thereafter with additional test force and then measuring depth of indentation after removal of additional test force (Remaining preliminary test force active) for measurement of Hardness Value.

Brinell test consists of forcing a hardened ball into surface of a test piece with a specified test-force and measuring the diameter of indentation for evaluation of Brinell Hardness number.

Operation :

For Rockwell & Rockwell superficial Test :

In case of 'RASN' series machines for Rockwell or Rockwell superficial tests, a preliminary test force is first applied without removing zero Quickly thereafter an additional test force is applied without removing the preliminary test force. When the penetration is stabilised, the additional test force is removed and the hardness number is shown directly on the indicator.

For Brinell Test :

The operation is exactly same as above. However, the diameter of impression is measured out side of machine by Brinell microscope. Brinell hardness number is found out by refering corresponding hardness tables showing hardness number against dia of indentation for specified ball diameter and test force.

- Suitable for Rockwell Tests

- Motorised for automatic operation cycie e load/unload

- Preliminary Test Force - 98 07N (10kgf)

- Addition. Test Force - 490.3, 882.6, 1373N (150, 90, 140kgf)

- Total Test Force - 588.4, 980.7, 1471N

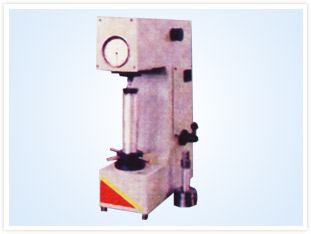

Rockwell Systems Hardness Testers - Model RASN

- Suitable for Rockwell Test

- Manually Operated

- Preliminary Test Force- 98.07, (10kgf)

- Additional test force - 490.4, 882.6, 137N, (50, 90, 140 kgf)

- Total Force Selection by external dailing

- Auto zero setting dial gauge

Rockwell Cum Brinell Testers - Model RASN (B)

- Same as RASN above, in additional

- Additional Test Force - 1471, 2354 N, (177.5, 250 kgf)

- Total Test Force - 1839, 2452 N, (187.5, 250 kgf)

Rockwell cum Rockwell Superficial Hardness Testers - Model RASN (T)

- Suitable for Rockwell & Rockwell superficial tests

- Manually operated

- Preliminary test force - 29.42, 98.07 N, (3.10 kgf)

- Additional test force - 177.7, 264.8, 411.9, 490.3, 882.8, 1373 N, (12.27, 42.50 & 140 kgf)

- Total test force - 147.1, 294.2, 441.3, 588.4, 980.7, 147 N, (15, 30, 45, 60, 100, 150 kgf)

- Auto zero setting dial gauge

Motorised Digital Hardness Testers - Model RASN (E)

- Digital Hardness Tester for Rockwell tests

- Motorised for automatic operation cycle ie. load / unload

- Preliminary test force - 98.07 N, (10kgf)

- Additional test force - 490.3, 882.6, 1373 N, (50, 90, 140 kgf)

- Total test force - 588.4, 980.7, 1471 N, (60, 100, 150 kgf)

- Test force selection by external dialing

- Set position with LED bar indicator for easy operation

- Key board entry through reliable membrane switches for scale / GO-NOGO/ dwell time selection

- Large size scale display for easy reading with 0.1 Rockwell resolution

- Parallel output for connection bot matrix printer to get result indication serial number of sets, Hardness scale, Hardness value and high / good / low indication.

'MCS' new 'RASN' series of Hardness Testing Machines come with much improved design and look with following major design changes

The machine body is having a taper front look and a big size dial gauge in the front. The machine is powder coated for far better look. The paint shade do not fade and machine looks like new over year.

The elevating screw of machine is guided in a hardened and ground bush, not allowing movement of elevating screw more than 0.05 mm when raised to full height The accuracy is retained for years together due to hardened bush

A hardened and ground stepped bush is fixed on top of main screw for location and test surface. This guarantees no change in results due to rough handling of test table or test piece. It means a trouble free long life machine accuracy.

An antifrication linear bearing with almost no clearance is provided for a perfect vertical movement of loading plunger with minimum friction This enables testing of small dia pin or ball upto 3 mm dia.

All machine models are provided with automatic zero setting dial gauge or digital readout. Hence zero setting at every test is avoided.

All four models confirm to respective standard as under

IS:3804, BS 10109-2 & ASTM E-18 for Rockwen Test

IS:5073 BS 10189-2 & ASTM E-18 for Rockwell Superficial Test

IS:2281 BS 10003- 2 & ASTME - 10 for Brinell Test

| Standard Accessories : | |||||

| Model | RASN |

RASN (B) |

RASN (T) |

RASN (M) |

RASN (E) |

| Testing Table 50mm dia | 1 |

1 |

1 |

1 |

1 |

| Testing Table 38mm dia with 'V' groove for round jobs 6-45mm dia. |

1 |

1 |

1 |

1 |

1 |

| Diamond lndentor - Rockwel |

1 |

1 |

1 |

1 |

1 |

| Steel Ball lndentor 1/16" with 5 spare balls |

1 |

1 |

1 |

1 |

1 |

| Steel Ball Indentor 2.5mm with 5 spare balls |

- |

1 |

- |

- |

- |

| Test Block Rockwell 'C' |

1 |

1 |

1 |

1 |

1 |

| Test Bock Rockwell 'B' |

1 |

1 |

1 |

1 |

1 |

| Test Block HB 2.5/187.5 |

- |

1 |

- |

- |

- |

| Test Block HR 30 N |

- |

- |

1 |

- |

- |

| Allen Soarers |

5 |

5 |

5 |

5 |

5 |

| Screw Drive |

1 |

1 |

1 |

1 |

1 |

| Clamping Device |

1 |

1 |

1 |

1 |

1 |

| Dash Pot Oil |

1 Bottle |

1 Bottle |

1 Bottle |

- |

- |

| Wooden Box for Std. Acessones |

1 |

1 |

1 |

1 |

1 |

| Telescopic Sleeves for Elavating screw protection |

1 Set |

1 Set |

1 Set |

1 Set |

1 Set |

| Spare Fuse 1 Amp |

- |

- |

- |

1 |

1 |

| Power cable |

- |

- |

- |

1 |

1 |

| Brinell Microscope |

- |

1 |

- |

- |

- |

| Machine cover |

1 |

1 |

1 |

1 |

1 |

| Instruction Manual | 1 |

1 |

1 |

1 |

1 |

| Technical Data : | ||||||

| Model | Unit | RASN | RASN (B) | RASN (T) | RASN (M) | RASN (E) |

| Major Load | N kgf |

588.4, 980.7, 1471 (60, 100, 150) |

588.4, 980.7, 1471, 1839, 2452 (60, 100, 150, 187, 5.250) |

147.1, 294.2, 441.3, 588.4, 980.7, 1471 | 588.4, 980.7, 1471 (60, 100, 150) |

588.4, 980.7, 1471 (60, 100, 150) |

| Minior Load | N kgf |

98.07 10 |

98.07 10 |

29, 42, 98, 07 (3,10) |

98.07 10 |

98.07 10 |

| Max. Test Height | mm | 230 | 230 | 230 | 230 | 230 |

| Depth of Throat | mm | 133 | 133 | 133 | 133 | 133 |

| Net weight Approx | kg. | 65 | 65 | 62 | 67 | 73 |

| Machine Dimensions (Approx) | mm | L-450 W-265 H-627 |

L-450 W-265 H-627 |

L-450 W-265 H-627 |

L-450 W-180 H-627 |

L-565 W-180 H-627 |

-

Optional Accessories :

- Steel Ball Indentor 1/8", 1/4", 1/2"

- Testing Table 200mm dia

- Testing Table 70mm dia with "V" groove for round jobs 10 to 80mm

- Van -Rest to support odd shaped jobs

- Jominy test fixture for end quench test

- Gooseneck Adaptor No.1

- Special Diamond lndentor suitable for Gooseneck Adaptor No.1

- Short nib diamond lndentor suitable for Gooseneck Adaptor No.1

- Gooseneck adaptor No.2

- Special Diamond Cylinder anvil for testing by jobs above 20mm dia.

- Everyball anvil with 25.4 dia or 38mm dia ball

- Gooseneck anvil for pipes 5 to 25mm ID with 5mm step inserts

- Jack rest for long and heavy jobs

- Dot matrix Pnnter for Model RASN (E)