Creep Testing Machines - For Metal

Introduction

MCS Series high temperature creep and relaxation testing machine uses advanced servo motor and ball screw actuator for precise loading application, load cells, electronic extensometers, MCS-MC01 controller, Motorized draw-head assembly automatically compensates for specimen elongation and keeps loading bar with excellent load accuracy of +/- 0.5%

Features

- Creep & Relaxation testing confirms to, ASTM E139, ASTM E292.

- Fully computerized, Automatic operation.

- Load capacity: 10 KN to 100kN. with Resolution 1/25000 of capacity.

- Single lever ratio of 1:10 or 1:20

- Pull rod assembly made of Super Alloy Materials.

- Three-zone vertical cylindrical furnace.

- High precision, high accuracy temperature controller.

- High temperature range from 100°C to 1000°C.

- Automatic load lever beam leveling device with over travel trips.

- Extension & deformation measurement with resolution 0.001mm

- Continuous temperature and strain measurements

- High temperature creep extensometer

- Prevents the draw head assembly from exceeding the limits during Manual or automation operations

- Provision to de clutch the motor from the gear assembly.

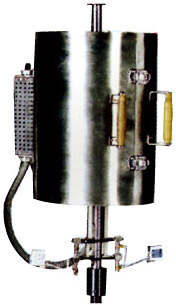

Furnace

- Furnace made of SS304 material

- Vertical split type design

- Single or Three zone model

- Close loop PID controller

- Temperature range (°C) 150-1200

- Temperature gradient 1 degree

- Temperature Error + 2°

- Use of K type thermocouple

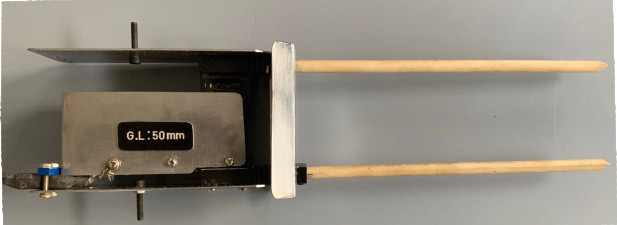

High Temp. Electronic Extensometer

- Suitable for metal, alloys, polymer, composites etc.

- Variable gauge length from 10 to 100 mm

- Extensometer resolution 0.001mm.

- Maximum extension 10 - 50% of gauge length

- Suitable for temperatures from (°C) 150 to 1200