Automatic Touch Screen Vickers Cum Brinell Hardness Testing Machines Manufacturer

MVM-250 TS

- MCS Make Hardness Testers of Vickers and Brinel Series are Designed and manufactured for very high accuracy, ease of operation, reliability and long-term stability

- These machines are suitable for checking Vickers or Brinell Hardness of steel and other metals, Load are applied with dead weights and are selected.

- The measurement of diagonal/Diameter of Indentation is done with help of built in touch screen. after taking the indentation on workpiece, the objective lens is automatically swivelled in position and indentation image appears on the focusing screen fitted in the front of the machine.

- Loading cycle is started with push button in the front where unloading is done manually by a hand lever.

- All models i.e.- MVM-120, MVM-120 S, MVM-250, MVM-250S, confirm to IS 1754 & BS 427 for Vickers & IS 2281 - 1983, BS 240, ASTM-E-10 for Brinell Hardness.

We are Manufacturer, Supplier, Exporter of Automatic Touch Screen Vickers Cum Brinell Hardness Testing Machines and our setup is situated in Kolhapur, Maharashtra, India.

Features :

- Major both Vickers & Brinell hardness of a metal in a one machine automatically.

- Auto and Manual Test mode for result Calculation.

- Easy load selection with push knob

- Load range from 5 kg to 250kg

- Industrial grade touch screen

- A precision indentation measurement

- Load accuracy ± 1%

- Facility to export results to PDF and Excel.

- High accuracy and repeatability of measurement.

- Wide testing range from soft metal to hard

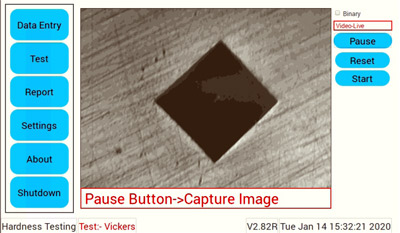

Vickers Test

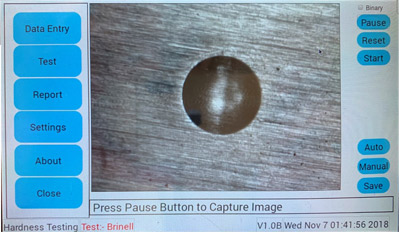

Brinell Test

Technical Specifications :

| Test Loads for Vickers Test | 5,10,15,20,30,40,50,60,100,120 kgf. |

| Test Loads for Brinell Test | 15.625,31.25,62.5,187.5,250 kgf |

| Optical Magnification | 35X, 70 X, 140 X |

| Max. Test Height (mm) | 200 |

| Throat Depth (mm) | 150 |

| Weight (Approx.) | 250 kg |

| Power Supply | 220 VAC, 50 Hz, 1 Phase |

Standard Accessories :

| Standard Test Block | 1 No. |

| Vickers Diamond Indenter | 1 No. |

| 2.5 mm Ball Indentor | 1 No. |

| 5 mm Ball Indentor | 1 No. |

| HV Standard Test Block | 1 No. |

| Brinell Test Block 187.5/2.5 HBW | 1 No. |

| Steel Ball Ø2.5 & Ø5.0 mm | 5 Nos. each |

| 5X Objective | 1 No. |

| 10 X Objective | 1 No. |

| Spanners | 1 Set |

| Electric Cord | 1 No. |

| Halogen Lamp | 1 No. |

| Telescopic Cover | 1 Set |

| Instruction Manual | 1 Book |