Dead Weight Tear Testing Machines (Drop Weight Tear Testers)

Introduction :

"MCS" developed it's first Drop Weight Tear Tester (DWTT) in the year 1999 for the maximum energy level of 30,000 Joules. Over the time, MCS commitment to excellence resulted in development of fully automatic PLC controlled DWTT with Hydraulic Shock Absorbers for drop weight tear testing of "Specimen" according to the standards ASTM-E436, API-RP5L3, ASTM-E208 and DIN EN 10274.

Now we offer three different automatic PLC controlled DWTTs;

• MCSTT-300000 J

• MCSTT-55000 J

• MCSTT- 80000 J

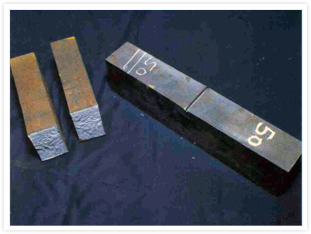

MCS DWTT is robust in construction, smooth in operation and is practically maintenance free. The machine is supplied with auxiliary equipment (optional). i.e. Hydraulic Notch Making Press and Deep Freezer to cool the specimen up to minus (-) 80°C.

Salient Features :- Drop weight tear testing of "Specimen" according to standards as per ASTM-E436, API-RP5L3, ASTM-E208 and DIN EN 10274.

- Touch-screen Panel with electronic display of height, energy drop weight and dropping speed at predetermined parameters.

- The stepless adjustable drop height is reached automatically after input of drop weight and energy.

- Drop weight is divided in individual weights to adjust drop energy.

- Modular frame design with stainless steel pillars and doors.

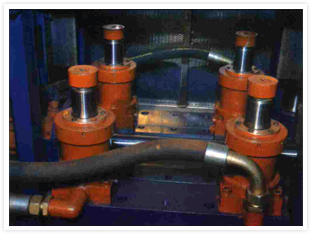

- Four high capacity hydraulic shock absorbers with accumulators for safe absorption of the excess drop energy.

- Hydraulic specimen feeding device, equipped outside of testing area.

- Easily removable bending tools (Hammer)

Safety :

- Electrical and rnechanical safety interlocking. Testing is possible only after checking of all safety parameters, to comply with OSHA requirements (USA).

- Exclusive safety bars provided to ensure human safety in case of catastrophic failures.