Computerized Universal Testing Machines Manufacturer

We manufacture computerized universal testing machines for all industries. These machines are highly result oriented and long lasting.

Features :

- Loading accuracy as high as ± 1%

- Servo control operation for load/strain rate control

- Manual as well as computerized control

- High temperature testing up to 1200 °C.

- Conforms to IS:1828, ASTM E8 Standards

The Controller MCS-MC01

- Latest flash micro controller with High speed data sampling

- Built in real time clock for date and time

- In built 4 channel data acquisition, expandable to 8 channel

- Load measurement using high precision pressure cell.

- 24 bit multiplexed ADC with 1/ 100000 counts for load.

- Displacement measurement by rotary encoder, Resolution 0.01mm

- Digital display of Load, Displacement, Extension, speed, Time

- Auto calibration for load, displacement and extension.

- Closed loop PID mechanism for precise load rate control.

- Stand alone machine operation from keyboard without computer

- Stepper motor/ servo valve interface for load/ strain rate control

- Sealed membrane keypad for data entry and running the test.

- In built 232/ USB port for real time data transfer to computer.

- Memory for storage of calibration factors & machine settings.

- Over load, over travel protection for all types of testing needs

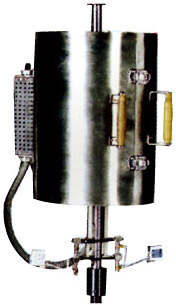

Model: MCS-UTE

- Furnace made of SS304 material

- Vertical split type design

- Single or Three zone model

- Close loop PID controller

- Temperature range (°C) 150-1200

- Temperature gradient 1 degree

- Temperature Error ± 2 degree

- Use of K type thermocouple

Extensometer Technical Data

MODEL |

Unit |

UTE-10 |

UTE-20 |

UTE-40 |

UTE-60 |

UTE-100 |

UTE-200 |

| Measuring capacity | (kN) |

100 |

200 |

400 |

600 |

1000 |

2000 |

| Measuring range | (kN) |

0-100 |

0-200 |

0-400 |

0-600 |

0-1000 |

0-2000 |

| Load Resolution | (N) |

10 |

20 |

40 |

60 |

100 |

200 |

| Load range with Accuracy of measurement ± 1% | (kN) |

2 to 100 |

4 to 200 |

8 to 400 |

12 to 600 |

20 to 1000 |

40 to 2000 |

| Resolution of piston movement (Displacement) | (mm) |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

| Clearance for tensile at fully descended working piston | (mm) |

50 to 700 |

50 to 700 |

50 to 700 |

50 to 800 |

50 to 850 |

50 to 900 |

| Clearance for compression test at fully descended working piston | (mm) |

0-700 |

0-700 |

0-700 |

0-800 |

0-850 |

0-900 |

| Clearance between columns | (mm) |

500 |

500 |

500 |

600 |

750 |

850 |

| Ram stroke | (mm) |

150 |

200 |

200 |

250 |

250 |

300 |

| Straining/Piston speed (at no load) | (mm/min) |

0 - 300 |

0 - 150 |

0 -150 |

0 - 100 |

0 - 80 |

0 - 45 |

| Power | kW |

1.0 |

1.0 |

1.7 |

1.9 |

2.6 |

4.9 |

| Voltage | V |

400 -440 |

400 -440 |

400 -440 |

400 -440 |

400 -440 |

400 -440 |

| Phase | 0 |

3 |

3 |

3 |

3 |

3 |

3 |

| Machine dimensions (Approx.- L x W x H) | (mm) |

2032x750x1960 |

2032x750x1960 |

2060x750x2180 |

2265x750x2534 |

2415x815x2900 |

3000x1200x3000 |

| Machine Weight (Approx) | kg |

1500 |

1500 |

2500 |

3500 |

5500 |

9500 |

Standard Accessories |

|||||||

| Tensile test - Clamping jaw for Round specimens of diameter |

(mm) |

10 - 20 20 - 30 |

10 - 20 20 - 30 |

10 - 25 25 - 40 |

10 - 25 25 - 40 40 - 55 |

10 - 25 25 - 45 45 - 70 |

20 - 40 40 - 60 60 - 80 |

| Tensile test - Clamping jaw for flat specimen Thickness Width |

(mm) (mm) |

0-10 10 - 20 - 50 |

0-10 10 - 20 - 50 |

0-15 15 - 30 - 65 |

0-15 15 - 30 - 70 |

0-22 22 - 44 44 - 65 70 |

0-20 20 - 45 45 - 70 90 |

| Compression- Pair of Compression plates of diameter |

(mm) |

120 |

120 |

120 |

120 |

160 |

220 |

| Transverse test Table with adjustable rollers width of roller |

(mm) |

160 |

160 |

160 |

160 |

160 |

200 |

| Diameter of roller | (mm) |

30 |

30 |

30 |

50 |

50 |

70 |

| Maximum clearance between supports | (mm) |

500 |

500 |

500 |

600 |

800 |

900 |

| Radius of punch tops | (mm) |

6, 12 |

6, 12 |

12, 16 |

16, 22 |

16, 22 |

30, 40 |

Test Conducted With Electronic Extensometer MCE-2