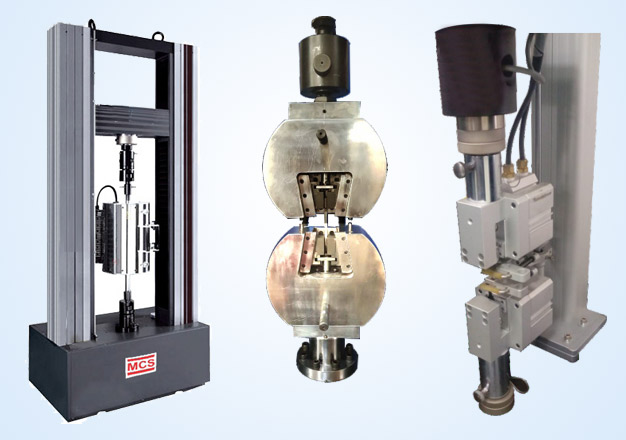

Computerized Tensile Testing Machines Manufacturer

We are Manufacturer, Supplier, Exporter of Computerized Tensile Testing Machines and our setup is situated in Kolhapur, Maharashtra, India.

Introduction

MCS make TNE series machines are electronic screw driven machines with precision screw and column construction and variable speed drive. These are high precision, high performance universal testing machines with maximum capacity up to 200 kN. The machines are suitable for studying mechanical behavior of various material like iron and metals, rubbers, plastics, ceramics, fabrics, composites, cables and wires.

- Standalone operation using MCS Controller.

- Double screw structure with recycling of ball-bearing.

- Variable speed drive with DC / AC servo driven options.

- Automatic identification and interchangeability of load cells.

- Different clamping devices to suit specific text requirement.

- Safety interlock by end limit switches and by overload sensing.

- Automatic return on termination of test.

- High temperature testing up to 1200°C.

- Confirms to IS, BS & ASTM standards for material testing.

- Creep & Stress relaxation up to 1000 hrs of testing.

The Controller MCS-MC01 :

- Latest flash micro controller with High speed data sampling

- Built in real time clock for date and time

- In built 4 channel data acquisition, expandable to 8 channel

- 24 bit multiplexed ADC with 1/ 100000 counts for load.

- Digital display of Load, Displacement, Extension, speed, Time

- Auto calibration for load, displacement and extension.

- Closed loop PID mechanism for precise load rate control.

- 16 bit DAC for DC/VFD drive with speed range 5- 500 mm/min

- Digital servo drive control, speed range 0.01- 1200mm/min.

- Sealed membrane keypad for data entry and running the test.

- In built 232/ USB port for real time data transfer to computer.

- Memory for storage of calibration factors & machine settings.

- Over load, over travel protection for all types of testing needs

SOFTWARE UNITESTPlus :

UNITESTPlus is the materials testing software developed under Microsoft's Licensed DotNet as front end and SQL server as database. This extraordinarily easy to use flexible software, allows the operator to control and monitor all aspects of the system from a single front end, ensuring fast, reliable and powerful testing & data analysis

The software can be used with wide range of material testing machines, to capture on-line data from MCS's state of the controller unit, using inbuilt USB port. Load, displacement, extension, machine parameters are transferred to computer at high speed to plot real-time & post test analysis.

UNITESTPlus comes with unmatched features as per the most Indian and International testing standards to support

all types of material testing applications.

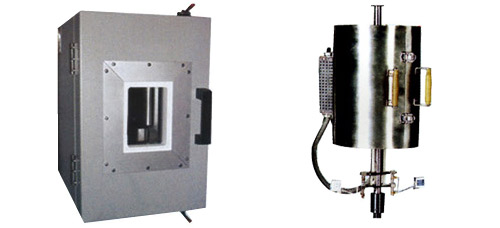

High Temperature Chamber / Furnace

- Single/ Three zone furnace made of SS304 material

- Vertical split type design with ceramic fiber insulation

- Close loop PID controller with controlled rate of heating

- Temperature range (°C) 150-1200

- Temperature gradient 1 degree with Error + 2°

- Temperature measurement using K type thermocouple

- Door central position observation window for chamber

- Supports Tensile, Compression, Cyclic, Torsion, Spring, Bend, Flexural, Peel, Spring and Relaxation Tests.

- Display of Load/Displacement/Extension/Speed/Strain & load Rate.

- Interface to extensometers with fixed /variable gauge lengths.

- Case sensitive help for operator for easy and accurate test set up.

- Multi-graph plotting of Load vs Disp, Stress vs Strain, Load vs time.

- Servo controlled (closed loop) operation using PID for precise. Load rate, Stress rate & Strain rate control.

- Extensive graphics with curve tracing/zooming facility.

- Results include UTS, Proof Stress, Young's Modulus, % Elongation, % Red in Area, Poissons ratio, Uniform strain, Area under curve.

- Unit changing facility like N, kN, kg, T, Mpa, KSI,PSI.

- Automatic on-line Proof Stress evaluation during test.

- PDF file generation, export to EXCEL facility.

- Statistical analysis (Mean, Mode,Median,std Dev, Max,Min,cp,cpk).

- Range of extensometers and deflectometers are available using encoder, strain gauge, LVDT, and laser technologies

- Wide range of universal type load cells up to 200kN

- Direct sample dimensions measurement interface as per ASTM d3767 using digital instruments/ gauges

- Pneumatic grips with regulation of closer pressure

- Wide range of grips for tension, compression, flexure, peel, shear, relaxation, pull out pull rod for high temp.

- Thermal chamber for performance with controlled temperature from -30 deg to 1000 deg

- Magnetic/glassscaleforaccurateelongation measurement

Technical Specification

| Type of tests | Tensile, Compression, flexural, Tear, Hysteresis, Peeling, Relaxation, Cyclic, Flexion. |

| Capacity | Up to 200 kN Auto Identification ofload cell installed |

| Load Resolution | Full scale / 50000. |

| Load cell accuracy | 0.5%or1 % as per ASTM E4 and ISO 7500-1 standard |

| Load Stress units | N, N/mm, N/mm2 (MPa), Kgf, Kgf/mm, Kgf/mm2, PSI, KSI |

| crosshead displacement | With 0.01 mm resolution by using rotary encoder/mangnetic scale |

| Elongation measurement accuracy | In compliance with ASTM E 83 Class E Standard |

| Test speed | from 0.05 to 1200 mm/min |

| Day light Clearance | 1000 mm (customized solution avalable) |

| Calibration | Certificate with reference to primary standards |

| Selection of sizes for graph representation of tests | Y axis: load, stress X axis: Differential / absolute elongation, time |

| Dimension measurement (optional) | Computer interface for Digital gauges for direct reading in compliance with ASTM D 3767 standards |

| Air pressure (for optional) | 6 bar for pneumatics grips |

| Thermal Chamber / furnace | from room temperature and 1200°C |

| Personal computer | Compatible with latest windows Operating system |

| Software usage Languages | English |